Water Reclamation Facility Expansion

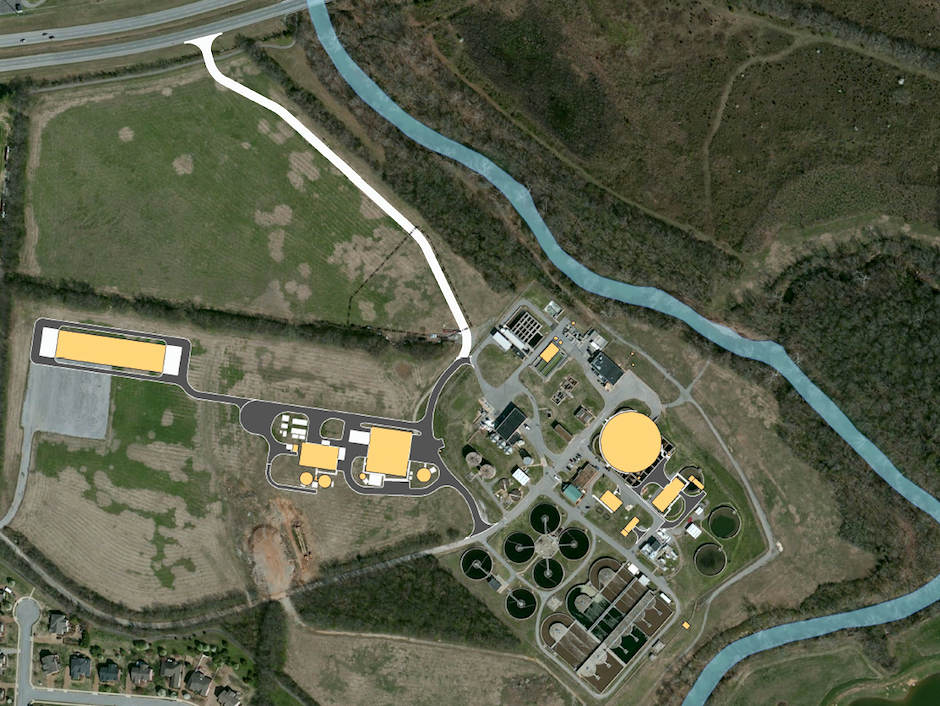

Surveying and civil-site engineering for modifications and expansion of the City of Franklin’s Sanitary Sewer Treatment Plant. Included precise locations of over 80 critical plant hydraulic components.Due to continued growth and development, the City of Franklin plans to expand the capacity of their existing Sanitary Sewer Treatment Plant from its current 12 MGD capacity to 16 MGD. As a sub to the prime design consultant, CIA provided surveying and civil/site engineering services for the modifications & expansion of the existing wastewater treatment plant and to modernize the solids processing operations.

Plant improvements include a new headworks facility, new 10 MG equalization basin, a new BNR basin splitter box, upgrades to the existing BNR Basins, upgrades to the clarifier distribution box, a new UV disinfection system, a new alum storage and feed system, a new centralized electrical building, new odor control facilities, and a host of plant wide piping upgrades and site demolition. Additionally, the plant expansion includes a new modern bio-solids handling facility including a new solids processing building, WAS storage, scum storage, new aerobic digesters and digester building, Thermal Hydrolysis Process, Combined Heat & Power Unit, FOG receiving and storage, odor control, and solar drying facilities.

Surveying services included a comprehensive topographic survey of the existing facilities and expansion area, survey of four remote RTU sites for SCADA upgrades, as well as providing updated sewer inventory on portions of the contributing sewer system for calibration of the sewer system model. CIA established on-site horizontal and vertical control with GPS and located with differential levels more than 80 critical vertical plant hydraulic points such as weir elevations to enable the design team to precisely analyze and design improvements to the plant’s hydraulics. In order to improve the sewer system model, approximately 40 existing manholes scattered throughout the city were recovered, opened, inverts identified and measured, and located both horizontally and vertically. The manhole data was compiled in GIS format compatible with the sewer model data.